In an era where durability and reliability are paramount, the importance of stainless steel fasteners cannot be overstated. According to a recent Market Research Future report, the global stainless steel fasteners market is projected to grow at a CAGR of 5.3% through 2027, driven by the increasing demand in construction, automotive, and aerospace industries. This growth indicates not only an expanding market but also highlights the necessity for using high-quality materials that can withstand harsh environments and diverse challenges.

Dr. John Smith, a renowned expert in the fastening industry, emphasizes that "the choice of stainless steel fasteners is critical for ensuring structural integrity and longevity of any project." His insights mirror the overarching trend of engineers and designers prioritizing stainless steel due to its corrosion resistance, strength, and versatility. As we delve into the top ten stainless steel fasteners to consider for every project, it becomes evident that selecting the right fasteners is crucial for optimizing performance and enhancing longevity in various applications. Whether it's for a simple DIY project or a complex engineering endeavor, understanding the types and benefits of stainless steel fasteners is essential for achieving success.

Stainless steel fasteners play a crucial role in a wide variety of applications, from construction to manufacturing, due to their resistance to corrosion, durability, and aesthetic appeal. Understanding their significance is vital for anyone involved in a project that requires reliable and sturdy fastening solutions. According to a recent industry report by Freedonia Group, the demand for stainless steel fasteners is projected to grow at a CAGR of 4.3% through 2024, underscoring their importance in modern engineering and construction.

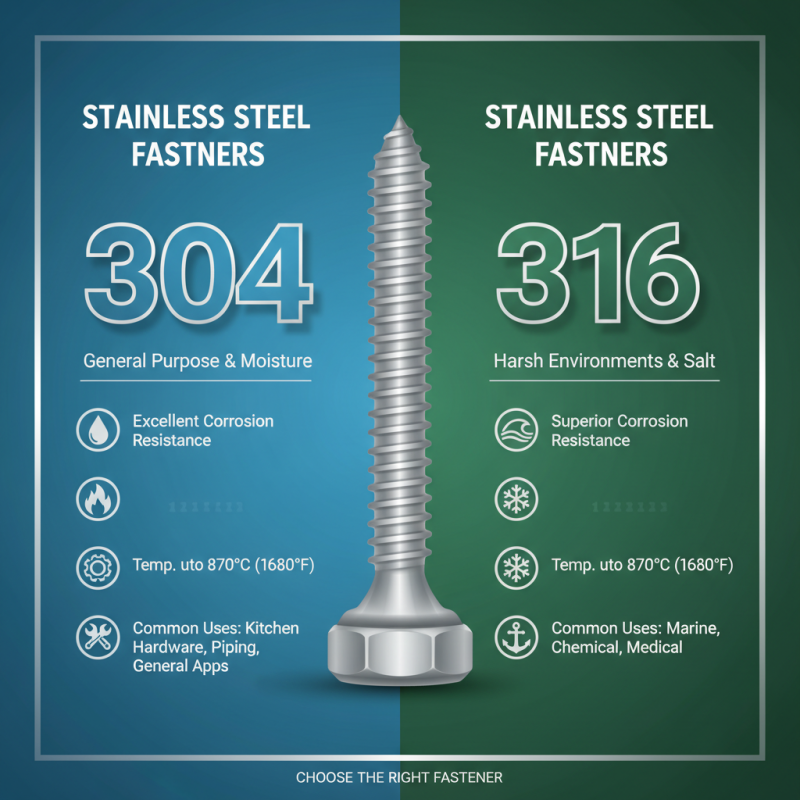

When selecting stainless steel fasteners, consider the specific environment they will be exposed to. For instance, the grade of stainless steel determines its resistance to corrosion and certain chemicals, which can vary significantly. Grade 304 is commonly used for its general corrosion resistance, while Grade 316 is preferred in marine environments due to its enhanced resistance to saltwater. Tips for choosing the right fastener include evaluating the environmental conditions, applying appropriate coatings for added protection, and ensuring the fastener's mechanical properties align with the load requirements of your project.

It's essential to match the fasteners with compatible materials to avoid issues like galvanic corrosion. This occurs when two different metals are in contact in the presence of an electrolyte, leading to deterioration. Proper installation techniques can also help prolong the lifespan of the fasteners. Always ensure threads are properly aligned and avoid over-tightening, which can lead to thread stripping and decreased holding strength. By paying attention to these details, you can ensure the reliability and longevity of your fastened joints in any project.

When selecting stainless steel fasteners for your projects, understanding the characteristics of different types of stainless steel is crucial. The most commonly used grades include 304 and 316 stainless steel. Grade 304 is known for its excellent corrosion resistance and is suitable for a wide range of applications, particularly in environments exposed to moisture and oxidation. This grade can withstand temperatures up to 870°C and is often used in kitchen hardware, piping, and other general-purpose applications.

On the other hand, 316 stainless steel offers enhanced resistance to corrosion, especially against chlorides and marine environments. This makes it the preferred choice for applications involving saltwater exposure, like in coastal areas or in the pharmaceutical and chemical industries. The addition of molybdenum contributes to its superior performance, allowing it to resist pitting and crevice corrosion. Understanding these distinctions will help you choose fasteners that ensure durability and longevity in your projects.

When selecting stainless steel fasteners for various projects, understanding their features and applications is crucial for ensuring durability and reliability. Stainless steel fasteners come in several types, each designed for specific uses. For instance, A2 stainless steel is commonly used in indoor applications due to its excellent resistance to corrosion in non-aggressive environments. In contrast, A4 stainless steel, also known as marine grade, is ideal for coastal projects as it can withstand harsh chemicals and saltwater exposure.

In addition to corrosion resistance, the strength and flexibility of stainless steel fasteners make them suitable for high-stress environments. Their ability to maintain integrity under extreme conditions is essential for constructions that face temperature fluctuations or mechanical stress. Projects such as building bridges, installing machinery, or constructing marine structures often benefit from the use of high-quality stainless steel fasteners due to their reliability. Choosing the right type based on specific project requirements ensures that structures remain safe and functional over time.

When selecting stainless steel fasteners for your project, understanding the right type for your application is crucial. Fasteners are essential components in ensuring structural integrity, and stainless steel is often chosen for its corrosion resistance, strength, and aesthetic appeal. According to a report from the Freedonia Group, the demand for stainless steel fasteners is projected to grow at an annual rate of 4.3%, highlighting the increasing reliance on durable materials in construction and manufacturing.

To select the right fasteners, consider factors such as the environment in which they will be used, the load capacity required, and the material compatibility. For instance, fasteners exposed to marine conditions should be of higher quality stainless steel to withstand saltwater corrosion. Additionally, the American Society for Testing and Materials (ASTM) provides specifications for different grades of stainless steel, emphasizing that using the correct grade can enhance the performance and longevity of the fasteners. By understanding these best practices, you can make informed decisions that align with industry standards and project requirements.

| Fastener Type | Material Grade | Corrosion Resistance | Common Applications | Head Type |

|---|---|---|---|---|

| Bolt | A2-70 | Excellent | Construction, Machinery | Hex |

| Screw | A2-50 | Good | Furniture, Appliances | Pan |

| Nut | A4-70 | Excellent | Heavy Equipment | Hex |

| Washer | A2 | Good | General Fastening | Flat |

| Anchor | A4 | Excellent | Concrete, Brick | Sleeve |

| Rivet | 304 SS | Good | Aircraft, Automobiles | Solid |

| Pin | 316 SS | Excellent | Machinery, Tools | Cylindrical |

| Stud | A2-80 | Good | Scaffolding, Construction | Threaded |

| Clamp | 300 Series | Good | Plumbing, HVAC | Various |

| Fastening Tie | A4-50 | Excellent | Seismic Ties | Flat |

When it comes to stainless steel fasteners, their longevity significantly hinges on proper maintenance practices. A study conducted by the International Stainless Steel Forum (ISSF) highlights that stainless steel typically has a corrosion resistance that can last decades if adequately maintained. Regular cleaning is crucial, especially in environments where fasteners are exposed to harsh conditions such as saltwater or industrial chemicals. Utilizing a mixture of warm water and mild soap can effectively remove contaminants that could compromise the integrity of the fasteners.

Additionally, the choice of stainless steel grade plays an essential role in performance. For instance, AISI 304 and AISI 316 grades are commonly recommended, with 316 alloy providing superior corrosion resistance in marine applications compared to 304. Maintaining an appropriate level of humidity and avoiding exposure to chlorides can further enhance the lifespan of these fasteners.

According to research from the American Iron and Steel Institute, implementing regular inspection schedules to identify signs of wear or corrosion can prevent premature failures, ensuring that projects remain safe and cost-effective over time.