Hanger bolts are essential components in woodworking and construction. These specialized bolts combine features of a screw and a bolt. Their design ensures a strong, secure hold in various materials. As DIY projects become increasingly popular, understanding the best uses for hanger bolts is crucial.

In many applications, hanger bolts provide stability. They assist in connecting structural components, like beams and posts. However, improper installation can lead to issues. It’s important to know the right techniques. Selecting the appropriate length and thread type significantly impacts effectiveness. Furthermore, not everyone realizes the diversity in their applications. Hanger bolts work well in both light and heavy-duty scenarios.

Maintaining precision in installation is key. Drill a pilot hole before inserting the hanger bolt. This prevents splitting and ensures accuracy. Though challenges may arise, such as alignment problems, patience is vital. In construction, taking time with each step can avoid costly mistakes later. Being aware of potential issues will lead to better results. When used correctly, hanger bolts can enhance the durability and safety of your projects.

Hanger bolts play a vital role in construction and manufacturing. They are designed for specific applications. In wood framing, hanger bolts provide superior fastening strength. They allow for secure attachment between different building components. This is crucial for structural integrity.

A recent industry report indicated that over 75% of construction professionals prefer using hanger bolts for heavy load applications. Their threaded ends ensure easy installation and reliable strength. In industrial settings, they are often used to secure equipment to steel structures. Proper installation techniques are essential. Misalignment or improper torque can lead to failures.

While hanger bolts offer great advantages, they also require careful selection. Choosing the right diameter and length is crucial for optimal performance. Many professionals overlook this step, which can result in unnecessary repairs and higher costs. Construction safety hinges on these small decisions. Inadequate fastening may lead to structural problems later on.

Hanger bolts are versatile fasteners. They are used in many applications. Understanding the specifications and types is crucial.

There are two main types: fully threaded and partially threaded. Fully threaded hanger bolts are great for securing objects in tight spaces.

Partially threaded ones are ideal for holding materials together, providing a solid connection. The diameter and length of the bolts vary, which affects their load capacity.

Choosing the right type is essential for strength and durability.

Tips: When installing, ensure proper alignment. This avoids stripping the threads. Use a pilot hole for easier installation. A wrench should fit snugly around the bolt head.

This prevents slippage during tightening. Always double-check torque specifications to avoid over-tightening, which can lead to failure.

Overall, hanger bolts serve specific needs. Proper selection and installation are key for success. Experiment with different types to find what works best for each project.

Hanger bolts are essential in many construction projects, offering durable and flexible fastening options. To install them properly, start with a pilot hole. The hole should be slightly smaller than the hanger bolt's diameter. According to the National Design Specification for Wood Construction, accurate hole placement can enhance load capacity.

Once the pilot hole is ready, align the hanger bolt, threading the nut on one end and the wood or metal component on the other. Tighten it securely, but be cautious. Over-tightening can weaken the joint, leading to potential failure. Instructive data from engineering studies indicate that misalignment may reduce strength by up to 30%.

It's crucial to consider load requirements before selection. The diameter and length of a hanger bolt can vary widely. Choose based on specific project needs. For heavier loads, a thicker bolt is recommended. However, avoid common pitfalls like using mismatched materials. This can compromise stability. Be mindful of environmental factors as well. Moisture can lead to corrosion, affecting longevity.

This chart illustrates the preferred use cases for hanger bolts across different materials. The data indicates that wood is the most common material where hanger bolts are utilized, followed by metal and concrete. The percentages represent the estimated popularity of each material type for hanger bolt installation.

When installing hanger bolts, many beginners make common mistakes that can lead to frustrating results. One common error is not marking the spot accurately. Accurate placement is crucial. A misaligned bolt can cause structural instability. Always double-check your measurements before drilling.

Another frequent mistake is over-tightening the bolts. It might seem logical to tighten them as much as possible, but this can strip the threads, making them ineffective. Use a torque wrench for precision. It ensures that you apply the correct amount of force and prevents damage.

Tips: Always use a pilot hole. This helps the bolt go in smoothly. A drill bit slightly smaller than the bolt works well. Also, consider the material you’re working with. Wood and metal require different techniques. Take your time to ensure everything fits perfectly. Don’t rush, as mistakes are costly.

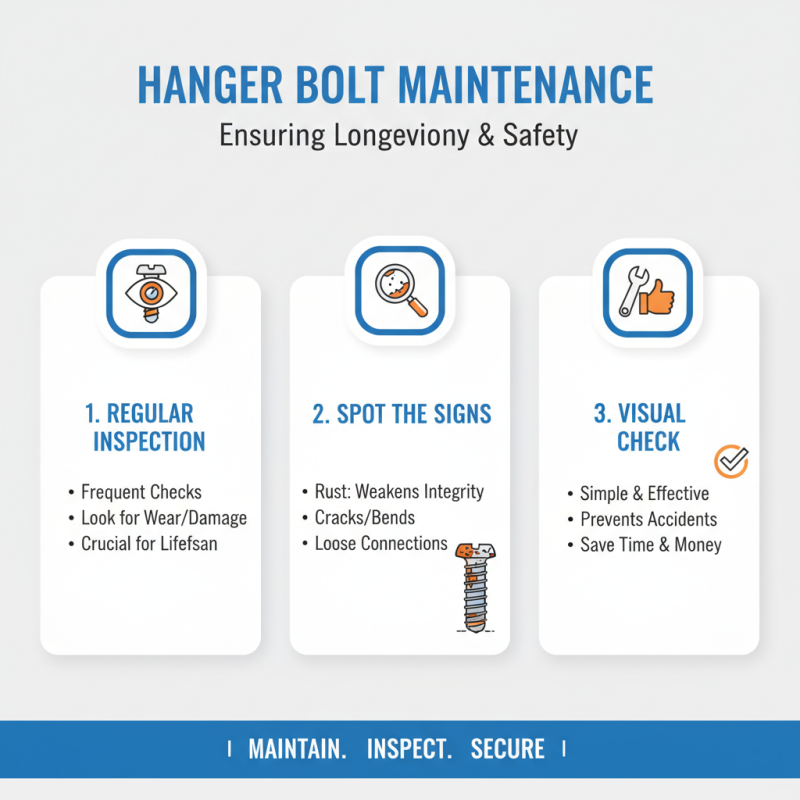

Regular maintenance of hanger bolts is crucial for their longevity. Inspect them frequently for signs of wear or damage. Look for rust, which can weaken the bolt's integrity. A simple visual check can often reveal issues that may go unnoticed.

Cleaning the hanger bolts is essential as well. Remove any dirt or debris that accumulates around them. Use a wire brush or a cloth for this task. This will help maintain their performance and prevent future problems. If you spot corrosion, consider replacing the bolts to avoid potential failures.

Always ensure the bolts are properly tightened. Loose bolts can lead to structure instability. Use a torque wrench for precise tightening. It’s a good practice to check the tension periodically. If you notice any components shifting, inspect the hanger bolts immediately. Neglecting these checks could lead to serious complications later on.