When it comes to DIY projects, the choice of materials can significantly impact the overall quality and aesthetics of the finished product. Among the various fasteners available, "Black Screws" have gained increasing popularity due to their ability to complement a wide range of design styles while providing sturdy and reliable support. According to a recent industry report by the Fastener Association, black screws account for nearly 20% of the fastener market share, highlighting their growing significance among professionals and enthusiasts alike.

Expert insights underscore the importance of selecting the right screws for each project. Dr. Emily Hart, a leading researcher in fastener technology, states, "Black screws not only offer a sleek appearance but also enhance corrosion resistance, making them ideal for both indoor and outdoor applications." This versatility ensures that users can find an appropriate solution for any DIY endeavor, whether it be furniture assembly, home repairs, or decorative installations.

As we delve into the top 10 best black screws for every DIY project in 2023, it becomes clear that understanding material specifications and intended applications is crucial for achieving optimal results. From finish and length to coating and thread design, the right choice will not only improve functionality but also contribute to the overall aesthetic appeal of your work.

When selecting black screws for your DIY projects, several key considerations can significantly influence your choice. First and foremost, it’s essential to evaluate the material of the screws. Common materials include stainless steel, carbon steel, and zinc-coated options. Stainless steel is known for its corrosion resistance, making it ideal for outdoor projects, while carbon steel offers strength for heavy-duty applications. For indoor projects, zinc-coated screws may suffice, providing a balance between durability and cost-effectiveness.

Another critical factor to consider is the screw type and size. Different projects may require specific screw types, such as wood screws, machine screws, or self-tapping screws. The size is also crucial, as using the wrong length or gauge can compromise the integrity of your work. Additionally, consider the head type—such as flat, round, or hex—depending on the finish you wish to achieve and the tools you plan to use. Ultimately, evaluating these aspects will help you select the best black screws tailored to your project’s unique requirements, ensuring both functionality and aesthetic appeal.

When selecting black screws for DIY projects, understanding the materials used is essential for ensuring strength and durability. Black screws are typically made from several materials, with each offering unique properties suited to specific applications. Steel, for instance, is one of the most common materials used in black screws due to its superior strength and resistance to bending. However, standard steel screws may be prone to corrosion unless coated with protective finishes like black oxide or zinc. These coatings not only enhance the aesthetic appeal of the screws but also improve their longevity, making them ideal for outdoor and high-moisture environments.

In addition to steel, stainless steel is another popular choice for black screws. Known for its excellent corrosion resistance, stainless steel screws perform well in challenging environments where exposure to moisture is inevitable. The added benefit of stainless steel is its ability to maintain structural integrity over time, which is invaluable for heavy-duty projects. Furthermore, there are specialty materials such as nylon or composite blends that offer lightweight options with good chemical resistance, suitable for applications where weight is a concern but strength is still required. Understanding these materials will enable DIY enthusiasts to select the right black screws tailored to their specific project needs, ensuring both performance and durability.

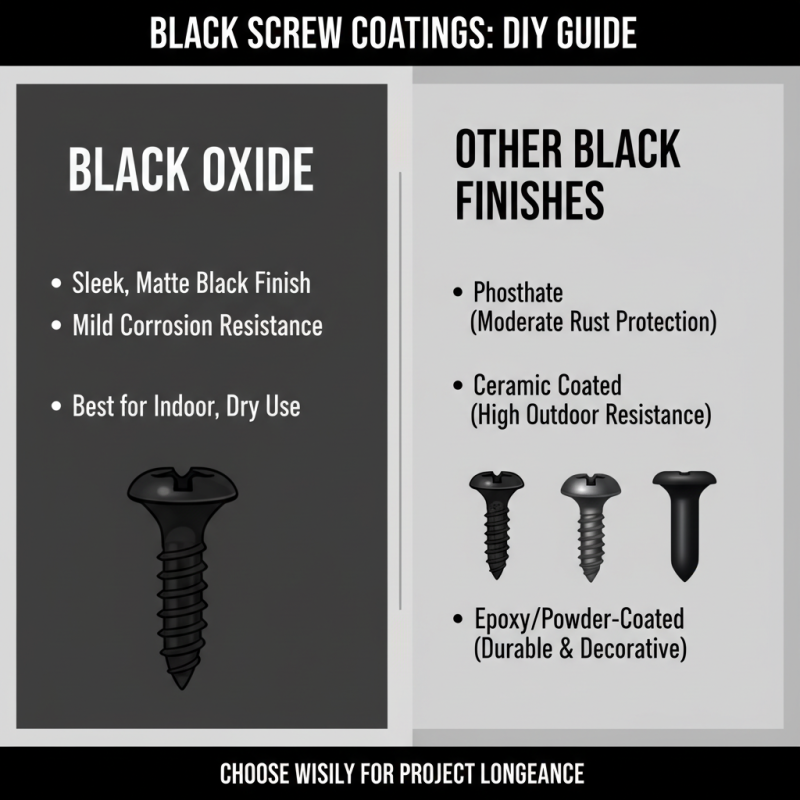

When selecting black screws for your DIY projects, understanding the common coatings and finishes is crucial, as they can significantly impact the performance and aesthetics of your work. The most prevalent coating for black screws is black oxide, which offers a sleek appearance while providing some corrosion resistance. However, it is important to note that while black oxide enhances the visual appeal, it may not provide the same level of rust protection as other finishes, making it less suitable for outdoor applications or environments with high humidity.

Another popular option is black zinc plating, which not only gives screws a striking look but also adds a layer of protection against rust and oxidation. This coating is particularly advantageous for projects requiring durability and longevity, as it withstands wear and tear better than non-coated screws. On the downside, the black zinc finish may be less attractive in high-heat applications, as it can degrade under extreme temperatures. Ultimately, selecting the right finish for black screws involves weighing the benefits of appearance and protection against the specific conditions they'll face in your DIY projects.

When embarking on a DIY project, understanding screw sizes and dimensional standards is crucial for achieving optimal results. Screws come in various lengths, diameters, and thread types, and selecting the right one can significantly impact the strength and durability of your work. For instance, using screws that are too short may not provide a secure hold, while overly long screws can damage materials or lead to structural weaknesses.

Moreover, different materials require specific screws to ensure compatibility and longevity. Wood screws often feature coarse threads that grip the wood effectively, while sheet metal screws are designed with finer threads for optimal performance in metal applications. It's essential to consider the material of your project when choosing screws, as this will determine not only performance but also the ease of assembly. By adhering to dimensional standards and understanding the specific requirements of your project, you can select the ideal screws that will enhance your efforts and ensure a successful build.

When selecting black screws for DIY projects, evaluating cost versus quality is essential to ensure longevity and reliability in various applications. Many consumers often find themselves torn between budget-friendly options and premium products that come with a higher price tag. While cheaper screws may initially seem appealing due to their lower upfront cost, they can result in long-term issues, including stripping, bending, or corrosion, which ultimately leads to decreased project durability.

Quality black screws generally feature better materials and finishes, providing enhanced resistance to environmental factors and wear. These screws often undergo stringent manufacturing processes that ensure consistency and reliability, making them suitable for a wide range of applications, from woodworking to metal fabrication. Investing in higher-quality options can significantly reduce the need for frequent replacements and repairs, offering better overall value in the long run. Consequently, careful consideration of both pricing and the quality of materials can lead to smarter choices, ensuring that every DIY project meets the desired standards of durability and aesthetics.

| Screw Type | Material | Size | Price ($) | Quality Rating (1-5) |

|---|---|---|---|---|

| Wood Screw | Steel | #8 x 1.5" | 5.99 | 4 |

| Self-Drilling Screw | Zinc-Plated Steel | #10 x 1" | 6.49 | 5 |

| Machine Screw | Stainless Steel | #6 x 1.25" | 4.89 | 4 |

| Lag Screw | Carbon Steel | #3/8 x 4" | 10.99 | 5 |

| Deck Screw | Coated Steel | #9 x 2.5" | 8.25 | 4 |

| Drywall Screw | Phosphate Coated Steel | #7 x 1.25" | 4.50 | 3 |

| Hex Head Screw | Alloy Steel | #1/4 x 2" | 7.75 | 5 |

| Philips Screw | Bronze | #10 x 3" | 9.00 | 4 |

| Screw Pin | Nickel Plated Steel | #1/8 x 1" | 3.20 | 3 |

| Coach Screw | Metal | #1/2 x 4" | 15.00 | 5 |